ULM carries forward a deep-rooted family legacy in mining, now led by a third generation that is truly passionate about the industry. Our journey is characterized by notable accomplishments. Throughout the years, we've successfully carved out our presence within the mining landscape, earning recognition for our adeptness in seizing opportunities and addressing challenges with efficiency and responsibility.

Who We Are ?

ULM Industries, a Moroccan mining firm, actively operates within high-value segments of the national mining ecosystem. Leveraging the extensive expertise of its Moroccan and international collaborators and partners, ULM Industries cultivates a dynamic knowledge base focused on identifying high-potential mining sites and facilitating their sustainable development. This commitment involves comprehensive engagement with local stakeholders and integration across various facets, including exploration, development, exploitation, and value addition, ultimately leading to marketing efforts both within Morocco and internationally.

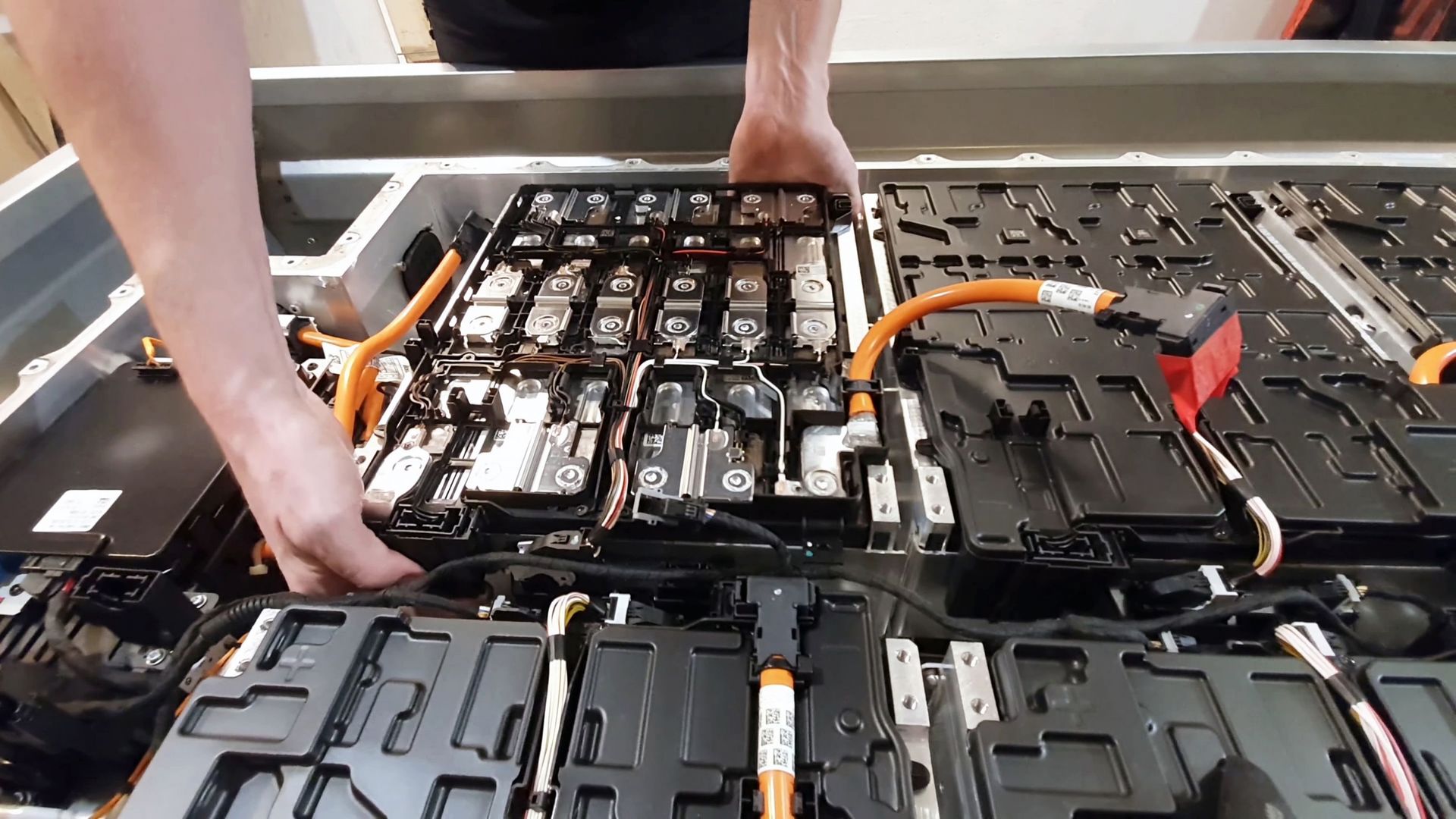

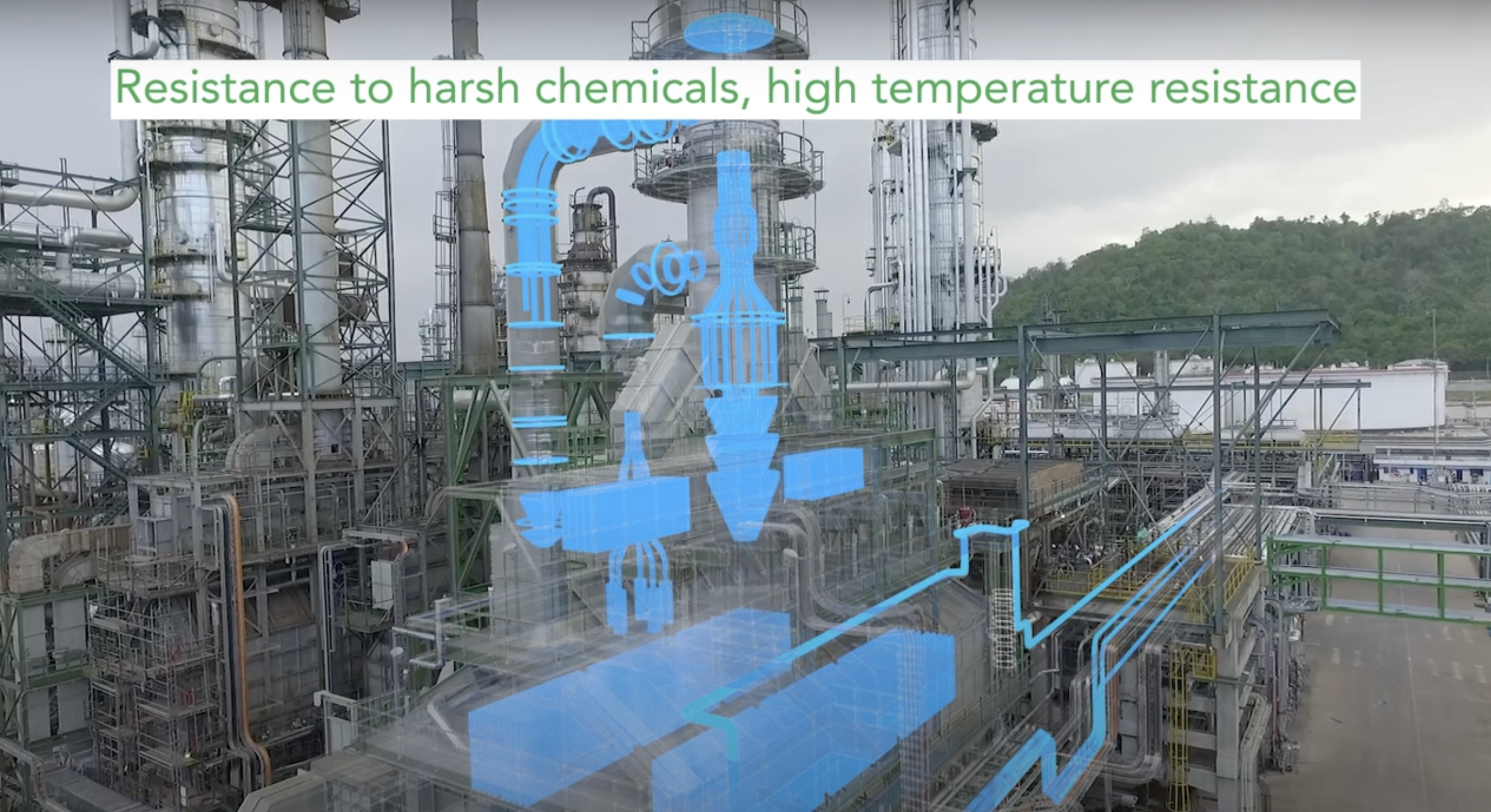

ULM Industries is steadfast in its promise to consistently and responsibly supply a diverse range of bulk or reclaimed mining materials, process equipment, industrial resources, and innovative solutions to its partner companies. This unwavering dedication significantly contributes to the ongoing global energy and technological transition, ensuring the delivery of environmentally responsible and cutting-edge solutions.

To ensure that all the different parts of its mining process work together smoothly, ULM Industries has built a network of top mining and industrial experts. They work not only in Morocco but also in some African countries. This network covers everything related to mining companies, like equipment, supplies, and chemicals.

To make sure they have the resources they need, ULM Industries does two things. First, they get their own mining permits. Second, they create long-term partnerships with other mining and industrial companies, both local and foreign.

ULM Industries also invests in mineral valorization and has two factories for this.

- One is in the Rabat region and can process 50 tons per day.

- The other is in the Taourirt region and can process 100 tons per day.

To foster a synergistic relationship among the diverse components of its mining value chain, ULM Industries has established a network in Morocco and select African nations. This network comprises leading mining and industrial entities that specialize in mining operations, process equipment, supplies, as well as chemical and para-chemical products.

ULM Industries is committed to providing its partner companies with a steady, environmentally responsible supply of a broad spectrum of raw or reclaimed mining materials, process equipment, industrial resources, and innovative solutions. These contributions play a significant role in supporting the ongoing global energy and technological transition led by ULM Industries.

ULM carries forward a deep-rooted family legacy in mining, now led by a third generation that is truly passionate about the industry. Our journey is characterized by notable accomplishments. Throughout the years, we've successfully carved out our presence within the mining landscape, earning recognition for our adeptness in seizing opportunities and addressing challenges with efficiency and responsibility.

Generate value for our teams, employees, customers, and partners by sustainably and responsibly producing and overseeing the essential mining materials required for the global industry and its transition towards cleaner energy.

Our real capital is you

Our key businesses

Exploration holds a key role in our strategic plan, contributing to our company's governance model. It maintains the sustainability and growth of our organic operations and allows us to seize new opportunities.

ULM Industries has been able to develop recognized mining expertise, stemming from its skilled employees and extensive experience in the field. This advantage enables us to develop high-value mining permits.

Integral to our mining value chain, we operate with experienced teams, appropriate equipment, and trusted partner subcontractors to exploit high-value ore deposits.

As an integrated mining chain participant, ULM Industries markets its own production, ensuring direct customer contact. Additionally, ULM forms partnerships with other operators to promote and market their products.

We represent established mining industry leaders in territorial matters, enhancing our reputation and fostering synergy across the value chain.

For the purpose of suggesting a complete offer, ULM Industries provides its customers with comprehensive logistics expertise, efficiently managing flows through innovative storage, handling, and transport solutions on these platforms. This optimization facilitates smoother resource distribution in the customer supply chain.

To secure sustainability and competitive positioning, ULM Industries collaborates with esteemed universities and laboratories in scientific partnerships.

It also provides continuous employee training to boost their potential and initiative.

As part of its activity, ULM Industries extends a wide array of equipment, industrial processes, and mining supplies to enrich its overall offering and strengthen synergy within the mining ecosystem components.

ULM in Numbers

++20

Partners

++20

Exploration Projects

++20

Industrial Operations

++20

Years of Experience

++100

Years of Mining Culture

++75

Collaborators

++100000t

Of Mineral Production

++1000000tt

Of Critical Mineral Resources

Our Minerals

Fluorine, also known as fluorite, is a mineral composed primarily of calcium fluoride (CaF2). It finds application in manufacturing specific lithium-ion battery electrodes, enhancing battery performance and efficiency. This, in turn, boosts energy density and prolongs battery life.

- Below, you'll find some of its applications across different fields:

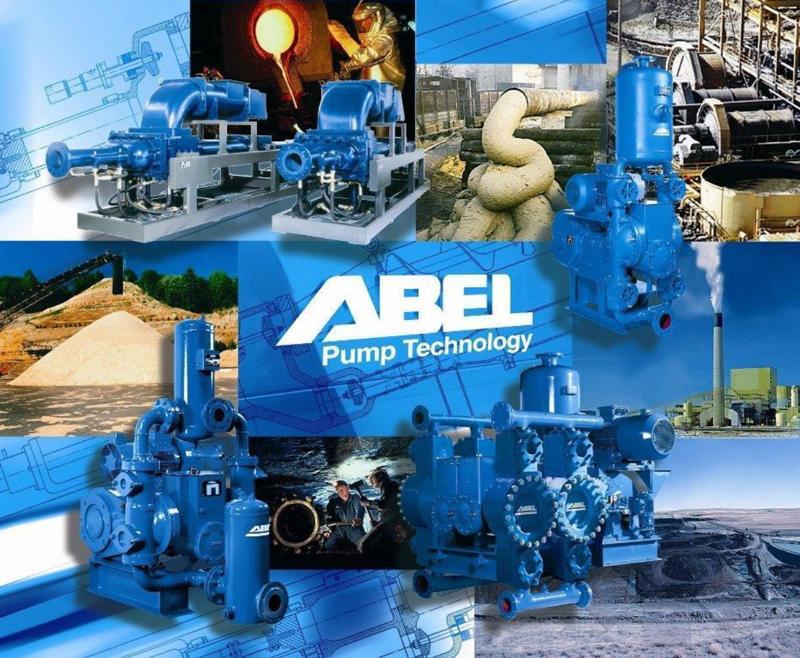

Representations

ULM Industries serves as the representative for various mining and industrial entities in Morocco. ABEL PUMPS TECHNOLOGY, a German multinational established in 1947, specializes in the production of volumetric pumps, notably diaphragm and piston pumps, as well as solid matter pumps.

For further details regarding the ABEL pump lineup and our array of mining and industrial offerings, kindly reach out to our sales department:

- Email : I.ouardi@ulmindustries.com

- Phone : +212-618-880-709

- Fix : +212-522-947-781

Media

Our publications

Our Gallery

Spontaneous application

Submit a spontaneous application by filling out this form

Français

Français